EvoSkate

Students work in teams to design and build a functional carbon fiber skateboard. They explore composite materials, prototype using vacuum curing, and complete the board with wheels, finishing, and surface grip.

- High School

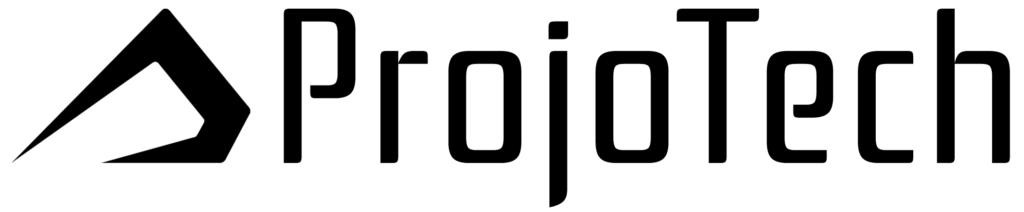

In this high-performance design challenge, students collaborate to research, design, and fabricate a carbon fiber skateboard using ProjoTech’s special composite kit (CarbonRide). The journey begins with deep research into carbon fiber composites, their material properties, and real-world applications—especially in sports equipment and lightweight product engineering. Students then analyze the design features of modern skateboards, including deck shape, concavity, material layering, and the roles of wheels and bearings in ride quality and speed.

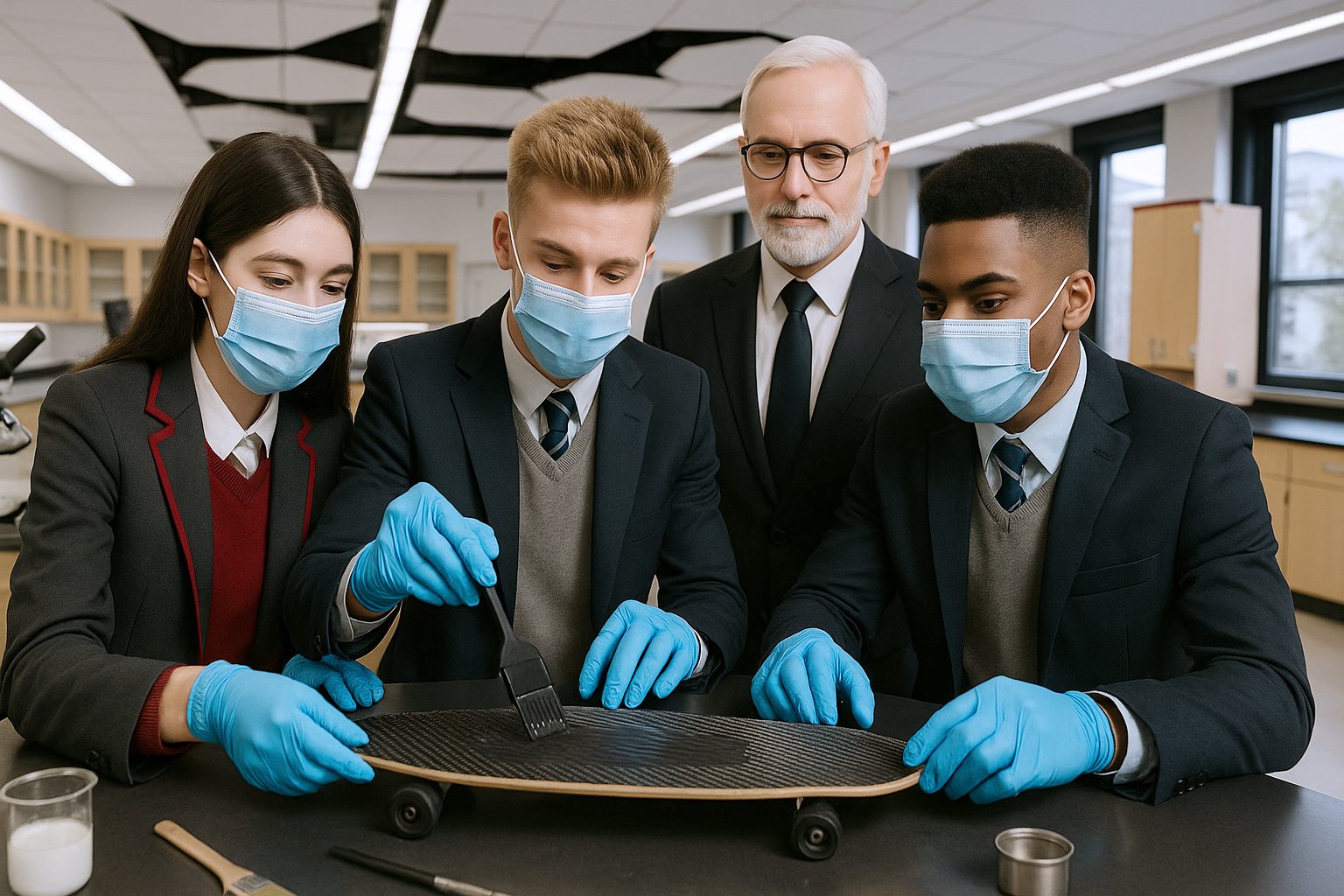

After brainstorming and planning, students move into prototyping using a supplied mold, foam core, carbon fiber mats, and epoxy resin. They apply the hand layup technique, then use a vacuum pump and curing bags to compress the layers and enhance bonding quality. Once cured, the skateboard undergoes finishing and polishing, followed by installing trucks, wheels, and anti-slip grip tape for safety and performance.

This project combines composite engineering, product development, and precision manufacturing into one real-world learning experience—empowering students to take an idea from research to a fully functional, professional-grade product.

For more Information:

For more Information:

- Detailed Project Plan following the Engineering Design Cycle for a high school.

- Assessment Criteria for each stage with level descriptors.

- Aligned with American Standards and practices (NGSS, CCSS, & ISTE).

- CarbonRide kit with Instructional video.

- Access to the Basic ProjoTech App on any web browser.

- Digital Resources and worksheets are allocated to different tasks.

- Comprehensive Teacher Guide.

- List of required tools and devices in the school.

For more Information: