Smart Parking System

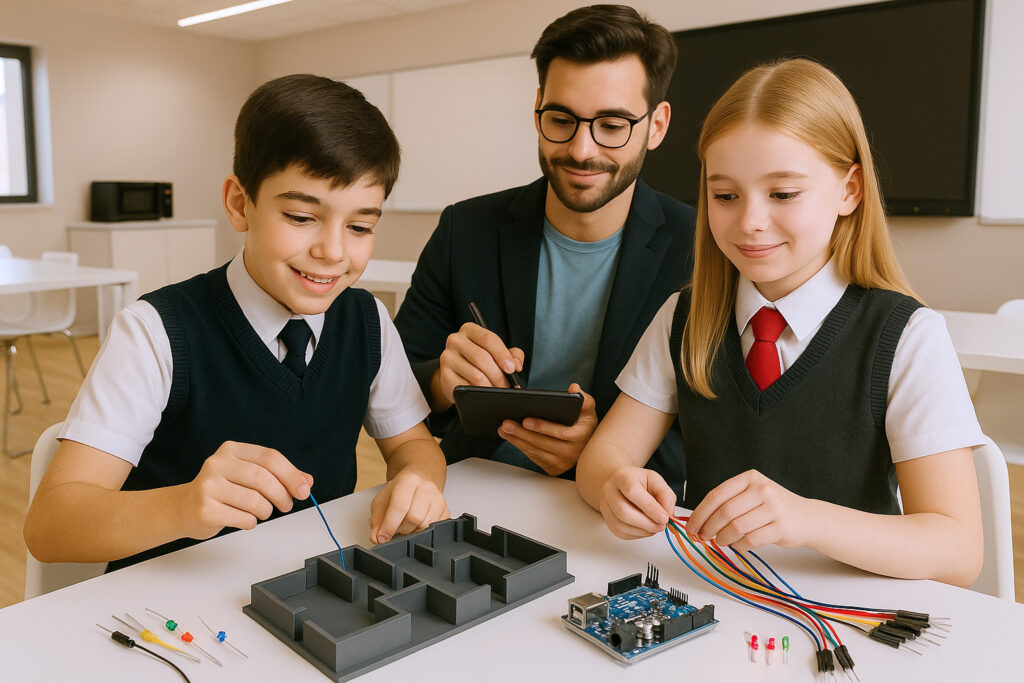

Students design and build a 3D-printed automated smart parking system using a cylindrical layout, vertical motion, rotation, and sliding. They integrate a microcontroller, sensors, and limit switches to operate and control the system.

- High School

In this advanced engineering and automation project, students design and build an automatic smart parking prototype replicating a real-world multi-level, rotating parking tower. The system is based on a cylindrical layout with vertical stacking and rotational plus sliding mechanisms to load and unload a model car to the correct parking slot.

Students begin by studying automated parking systems and understanding the principles of vertical transport, mechanical rotation, rail sliding, and positional control. Using ProjoTech’s special kit (AutoPark360) and guided by ImmersiView 3D instructions, students 3D print structural components, including car trays, guides, motor mounts, and gear systems.

The assembly integrates a vertical linear motor, a rotational platform, and a sliding tray system, all controlled by a microcontroller. Students wire limit switches to detect motion boundaries, ensuring safe transitions between parking levels and rotations.

Once assembled, students upload the code to control motion sequencing, test system functionality, and calibrate all movement components for smooth operation. Through iterations, they analyze system performance and refine timing and position accuracy.

This project offers a comprehensive learning journey in mechatronics, 3D printing, control systems, and automation, simulating how smart infrastructure can solve real urban challenges.

For more Information:

For more Information:

- Detailed Project Plan following the Engineering Design Cycle for a high school.

- Assessment Criteria for each stage with level descriptors.

- Aligned with American Standards and practices (NGSS, CCSS, & ISTE).

- AutoPark360 kit with ImmersiView integration.

- Access to the Basic ProjoTech App on any web browser.

- Digital Resources and worksheets are allocated to different tasks.

- Comprehensive Teacher Guide.

- Supporting Documents: Full tested Code, 3D models of robot parts ready for 3D printing.

- List of required tools and devices in the school.

- Optional Skills & Standards Achievement features.

For more Information: